For businesses that rely on precise temperature control, such as restaurants, floral shops, breweries, and meat processors, a reliable commercial walk-in cooler is essential. These units provide versatile storage for perishable goods, helping maintain freshness, reduce waste, and streamline operations. Choosing the right cooler requires careful consideration of size, temperature requirements, refrigeration systems, and site logistics.

Determine the Right Size and Capacity

Proper sizing ensures efficient storage and workflow. Undersized units risk overcrowding and uneven cooling, while oversized units waste energy.

· Estimate inventory and peak demand: Assess the volume of perishable goods handled daily and during peak periods. Factor in bulk deliveries and seasonal fluctuations.

· Plan the layout: Shelving and racks maximize vertical space, while clear aisles enable easy access and efficient use of cold air circulation. Proper layout supports faster workflow and maintains consistent temperatures throughout the cooler.

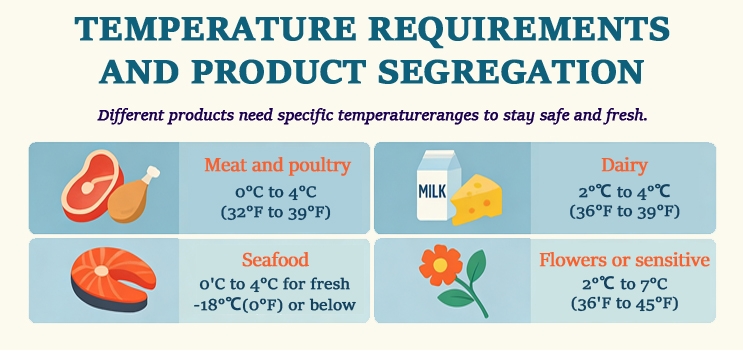

Temperature Requirements and Product Segregation

Different products need specific temperature ranges to stay safe and fresh:

Typical ranges:

· Meat and poultry: 0°C to 4°C (32°F to 39°F)

· Seafood: 0°C to 4°C for fresh, -18°C (0°F) or below for frozen

· Dairy: 2°C to 4°C (36°F to 39°F)

· Flowers or sensitive produce: 2°C to 7°C (36°F to 45°F)

Zoning and separation: Partitioned sections or separate zones prevent cross-contamination and odor transfer, allowing for precise temperature control for multiple product types within the same unit.

Refrigeration System and Energy Efficiency

A high-quality refrigeration system ensures stable temperatures and long-term efficiency.

· Compressor and condenser selection: Common options include piston, screw, or scroll compressors with air-cooled or water-cooled condensers. The choice depends on cooler size, ambient conditions, and maintenance capacity.

· Insulation and panels: PU or PIR sandwich panels with 150–250mm thickness provide excellent thermal performance. Properly sealed joints prevent cold bridges and energy loss. Floors should be durable and frost-resistant.

· Energy-saving strategies: Efficient airflow, LED lighting, automatic defrost cycles, and reliable temperature monitoring all reduce energy consumption while preserving product quality.

Installation and Site Considerations

Even a high-quality cooler requires proper installation to perform reliably.

· Power supply: Confirm that your facility can meet voltage and amperage needs. For unstable grids, consider backup generators.

· Ventilation and maintenance access: Adequate airflow for condensers and easy access to compressors, evaporators, and panels ensure optimal operation and simplify routine maintenance.

· Delivery and positioning: For container-style or modular units, prepare the site with level ground, sufficient clearance, and pre-cooling before loading goods.

Quick Buy Checklist

Before purchasing, ask your supplier:

1. What size and capacity suit my daily and peak demand?

2. How many temperature zones or product segregation options are available?

3. Which compressor and condenser types are included, and how energy-efficient is the system?

4. What are the installation requirements, including power, ventilation, and site clearance?

5. Is the unit NSF-approved for commercial food storage and supported by a warranty?

A well-chosen commercial walk-in cooler improves operational efficiency, protects perishable goods, and reduces waste. Focusing on proper sizing, precise temperature control, high-quality refrigeration, and installation readiness will ensure your cooler serves your business reliably for years.