Introduction

Commercial freezers are essential in restaurants, supermarkets, and food processing facilities. Their reliability directly impacts food safety, energy efficiency, and overall operating costs. Regular preventive maintenance not only extends the life of the equipment but also minimizes unexpected breakdowns.

Below is a practical guide covering daily, periodic, and annual maintenance routines, along with solutions to common problems.

Daily and Weekly Maintenance

The best way to avoid costly repairs is by building small habits into your routine:

· Surface Cleaning: Wipe the doors, handles, and exterior surfaces with a soft cloth to maintain hygiene and appearance.

· Check Door Gasket: Ensure the door seal is intact and airtight. A simple test is to close the door on a dollar bill. If you feel resistance when pulling it out, the seal is good.

· Listen for Sounds: Pay attention to unusual noises during compressor startup or operation—this could indicate developing issues.

· Temperature Monitoring: Log the temperature daily using the built-in or external thermometer. Freezers should consistently maintain -18°C (0°F) or below.

Tip: Keep a maintenance logbook for staff to record daily checks. It helps spot recurring problems early.

Tip: Keep a maintenance logbook for staff to record daily checks. It helps spot recurring problems early.

Periodic Maintenance (Monthly/Quarterly)

Every few weeks or months, depending on your working environment, schedule deeper maintenance tasks:

Thorough Interior Cleaning

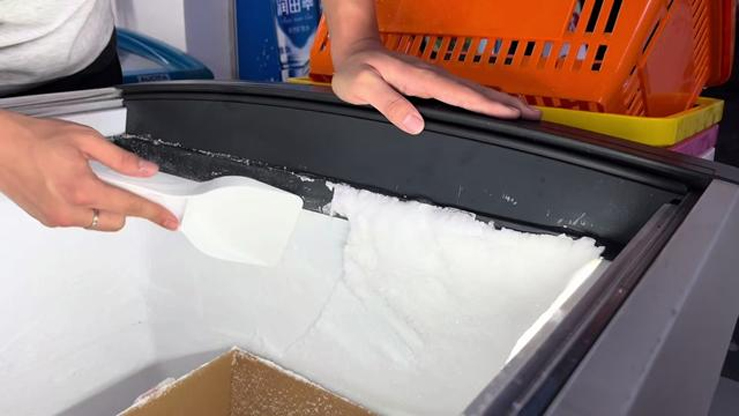

· Power Off & Defrost: Always unplug the freezer before cleaning. For manual defrost models, let frost melt naturally—never use sharp tools to chip away ice.

· Wash & Rinse: Clean walls, shelves, and drawers with neutral detergent and warm water. Pay special attention to the folds of the gasket.

· Clear the Drain Hole: Flush with warm water and unclog gently with a soft stick.

· Dry Completely: Use a dry cloth before restoring power to prevent ice build-up.

Clean Condenser Coils

One of the most critical steps for efficiency and longevity:

· Locate & Clean: Found on the back or bottom, the coils resemble a grid. Use a vacuum or soft brush to remove dust and lint.

· Why it Matters: Dirty coils reduce heat dissipation, causing higher energy consumption and even compressor failure.

· Frequency: Quarterly cleaning in dusty kitchens; every six months in cleaner environments.

Annual Professional Service

Even with regular upkeep, professional inspection is essential once a year:

· Refrigerant Check: Detect and repair any leaks.

· Compressor Inspection: Ensure smooth operation and proper electrical current.

· Electrical Circuit Check: Tighten connections and inspect for wear.

· Thermostat Calibration: Verify accurate temperature control and display.

Tip: Partner with a trusted refrigeration service provider. Preventive service costs far less than emergency repairs.

Tip: Partner with a trusted refrigeration service provider. Preventive service costs far less than emergency repairs.

Common Issues and Quick Self-Checks

Even with regular maintenance, problems may occur. Here are common signs and possible causes:

· Temperature Too High: Caused by a faulty gasket, dirty coils, overloading with warm food, refrigerant leaks, or fan failure.

· Excessive Frost Build-up (Direct Cool Models): Usually due to irregular defrosting or a damaged door seal.

· Unusual Noises: Fan blades hitting ice, loose compressor mounts, or vibrating pipes.

· Water Pooling at Bottom: Often linked to clogged drain holes or poor door seals allowing condensation.

Safety First

While minor issues like cleaning or gasket replacement can be handled in-house, anything involving electrical circuits, refrigerant, or the compressor should be left to certified technicians. Always disconnect the power supply before inspection or cleaning.